-

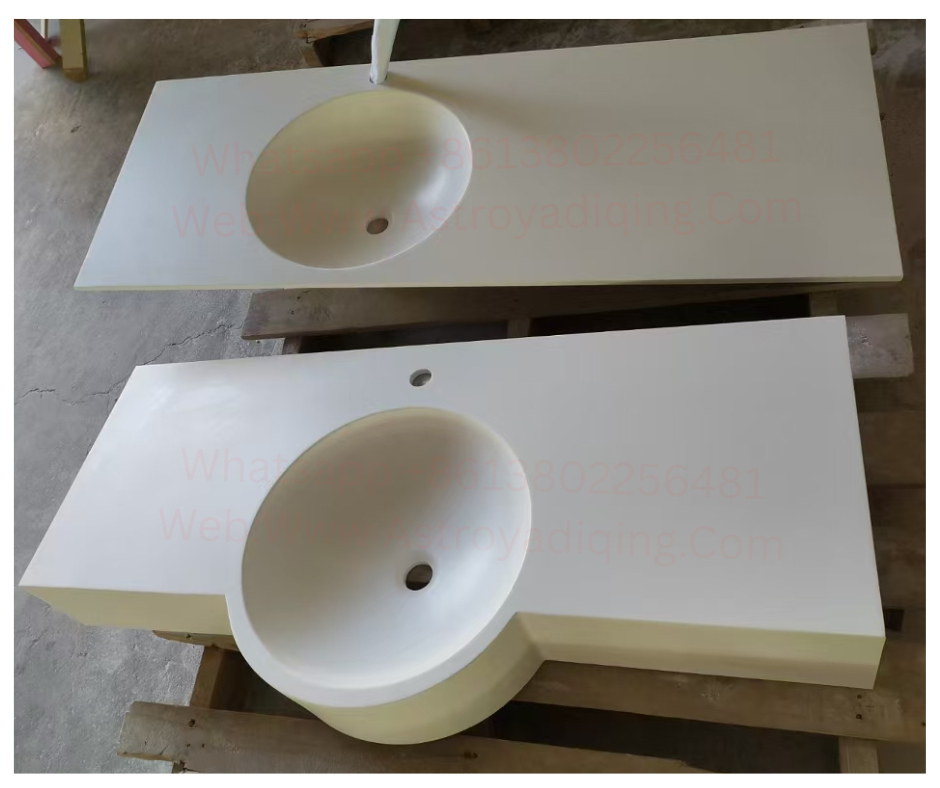

CUSTOMIZED WASHBASIN

Custom-made Large-bellied Washbasin Bathroom Fixtures

PN: Large-bellied Washbasin

Style: Thin-rimmed/Thick-rimmed

Material: Imported American Corian Acrylic

Model: ZLT-2270 Basin

Dimensions:

A: 2400520157mm (Inner basin: 600370130)B: 2400520157mm (Inner basin: 700370130)

Customization Accepted: Provide design drawings/dimensions

Minimum Order Quantity: 1 unit/month

Customization based on customer specifications

Transaction Method: TT/Wire Transfer

Custom Delivery Time: 12 days

FACTORY CUSTOMIZATION CONTACT:WhatsApp +8613802256481

ORIGIN: Guangzhou, China (Manufactured)

PACKAGING METHOD: WOODEN FRAME

CUSTOMIZATION PROCESS

CUSTOMIZATION PROCESS

1. Needs Communication and Solution Design: The customer clearly defines the size, shape, and purpose of the product. For pure acrylic artificial stone material, design drawings in CAD and other formats can be provided. If no drawings are available, a solution will be developed in collaboration with the manufacturer's design team. The effect can also be previewed and adjusted through 3D models.

MATERIAL VERIFICATION QUOTATION CONTRACT SIGNING:

2. The manufacturer provides relevant certifications for the imported acrylic sheets, confirming that they comply with RoHS and other standards (new imported pure acrylic artificial stone raw materials). After both parties confirm the solution, the manufacturer calculates the cost quote. Upon reaching an agreement, a contract is signed, specifying quality, delivery time, and other terms.

3、CUSTOMER AND SAMPLE PRODUCTION AND CONFIRMATION:

The manufacturer produces samples according to the plan. During this process, the imported boards will undergo constant temperature storage pretreatment to eliminate internal stress. After the samples are completed, they will be delivered to the customer for inspection. Once the materials and processes are confirmed to be correct, mass production will begin.

4、SAMPLE PRODUCTION CONFIRMATION FOR CLIENT AND FOREIGN TRADE REPRESENTATIVE:

The manufacturer produces samples according to the design. During this process, the imported sheets undergo temperature-controlled storage pretreatment to eliminate internal stress. After the samples are completed, they are delivered to the client for inspection. Once the materials and workmanship are confirmed to be correct, mass production begins.

5、QUALITY INSPECTION PACKAGING:

Quality inspectors check the dimensions of the products and whether there are scratches on the surface. Qualified products are then wrapped with protective film, bubble wrap, etc., to avoid damage during transportation. Finished products are then packed in wooden frames.

6、DELIVERY AFTER-SALES SERVICE:

After inspection, the goods are packaged with bubble wrap and sturdily crated with wooden frames. They are loaded onto trucks in bulk or containers. The goods will remain intact and undamaged.

get a quote